To bleed an oil boiler, switch the boiler off, locate the bleed screw on the oil pump, loosen it slowly, and release trapped air until a steady flow of oil appears. Once oil runs smoothly with no bubbles, tighten the screw securely and restart the boiler to restore normal heating operation.

Oil boilers remain a trusted and efficient source of home heating throughout the United Kingdom, particularly in rural properties without access to the gas grid. However, like any heating system, they occasionally need basic maintenance to keep them working smoothly. One issue that homeowners often encounter is trapped air in the system, which can lead to radiators not heating properly, reduced water circulation, higher fuel usage and even boiler lockouts. When this happens, knowing how to bleed an oil boiler correctly can save time, money and prevent unnecessary call-outs.

Bleeding a boiler is not complicated, but it must be done safely, in the correct order and with the proper tools. This detailed guide explains what bleeding is, why it matters, how to identify signs of trapped air, which tools you need, and the correct step-by-step method for bleeding the boiler and restoring proper performance. This long-form blog will offer everything a homeowner needs to confidently handle this essential task, including when professional assistance may be required.

What Does Bleeding an Oil Boiler Mean?

Bleeding an oil boiler refers to removing trapped air from the boiler or heating system. When air enters the lines, pipes, radiators or burner assembly, it disrupts the smooth flow of heating oil or hot water. This can lead to inefficient combustion, reduced heat output, and system noise. By releasing the built-up air, the oil can flow freely again, allowing the system to work at maximum efficiency.

Air most commonly enters an oil boiler system due to:

- Running out of heating oil

- Maintenance or repairs that open the system

- Air leaks in fittings or fuel lines

- Pumping or circulation issues

- Sludge buildup that creates air gaps

- Faulty valves or seals

Bleeding restores normal operation and is a standard part of maintaining a clean and efficient system.

Why Bleeding an Oil Boiler Is Important

If air is allowed to remain trapped in the boiler system, it can cause a range of performance and safety issues. Common problems include:

Reduced heating efficiency

The burner may not receive the correct amount of oil, resulting in more fuel being used for the same amount of heat.

Radiators are not heating properly.

Air trapped in the system prevents hot water from circulating fully, leading to cold spots, especially in upstairs rooms.

Boiler lockout

Many boilers shut down automatically when they detect poor fuel flow or combustion issues. If your boiler regularly locks out, trapped air may be the cause.

Damage to components

Excess strain on pumps, valves, burner heads and the circulating system can shorten the lifespan of internal parts.

Noisy operation

Gurgling, tapping or banging noises in radiators or pipework often result from trapped air bubbles.

Energy waste

Running a boiler with poor combustion or reduced efficiency wastes oil and money.

Bleeding the system promptly helps restore safe and efficient operation before these problems escalate.

Signs That Your Oil Boiler Needs Bleeding

Many homeowners only bleed their boiler once performance issues become noticeable. The most common warning signs include:

Radiators with cold spots

If the top of a radiator is cold and the bottom is warm, trapped air has displaced the hot water.

The boiler is repeatedly locking out.

A flame failure or burner shut-off may result from inadequate fuel delivery.

Noise from pipework or radiators

Gurgling or tapping noises mean air is trapped in the system.

Sluggish heating

If the heating system takes longer than usual to warm up, circulation may be obstructed.

Visible bubbles in the oil feed line

Clear filter housings or inspection points may show bubbles moving along the pipe.

Visible pressure drops

In some systems, air pockets can reduce system pressure, indicating the need for bleeding.

Once one or more of these symptoms appear, bleeding should be carried out as soon as possible.

Is Bleeding a Boiler Safe?

Yes, bleeding an oil boiler is safe when carried out correctly. It is not the same as bleeding gas equipment, which should only be done by a Gas Safe engineer. However, there are circumstances where professional help is advisable. If you are unsure about performing the procedure, or if the issue recurs frequently, a heating technician should inspect the system for leaks or mechanical faults.

Tools and Equipment Needed

Fortunately, bleeding an oil boiler requires very few tools. Most households already have what is needed:

- A boiler manufacturer’s handbook, if available

- A radiator bleed key or a flat-head screwdriver

- A clean cloth or a small container to catch any oil or water

- Protective gloves

- A spanner if the bleed screw needs loosening

- Access to the oil tank to confirm the supply

In older systems, you may also need access to the oil pump purge screw. Always ensure the boiler is switched off and safe to work on before beginning.

Preparing the Boiler

Before bleeding the system, carry out these checks:

Confirm there is heating oil in the tank

Many cases of trapped air occur when the boiler runs dry. After refilling, air bubbles can enter the lines and must be removed before the burner can reignite properly.

Switch off the boiler.

Always shut down the boiler at the main control switch and allow components to cool. This prevents accidental ignition while working.

Check the boiler manual.

The location of bleed points can vary between models. If you have the manual, refer to the recommended bleeding instructions.

Ensure the work area is well-lit and well-ventilated

Bleeding the boiler correctly means maintaining proper visibility and safety.

Once the system is prepared, you can begin the bleeding process.

Step-by-Step Guide: How to Bleed an Oil Boiler

Step 1: Locate the Bleed Valve or Screw

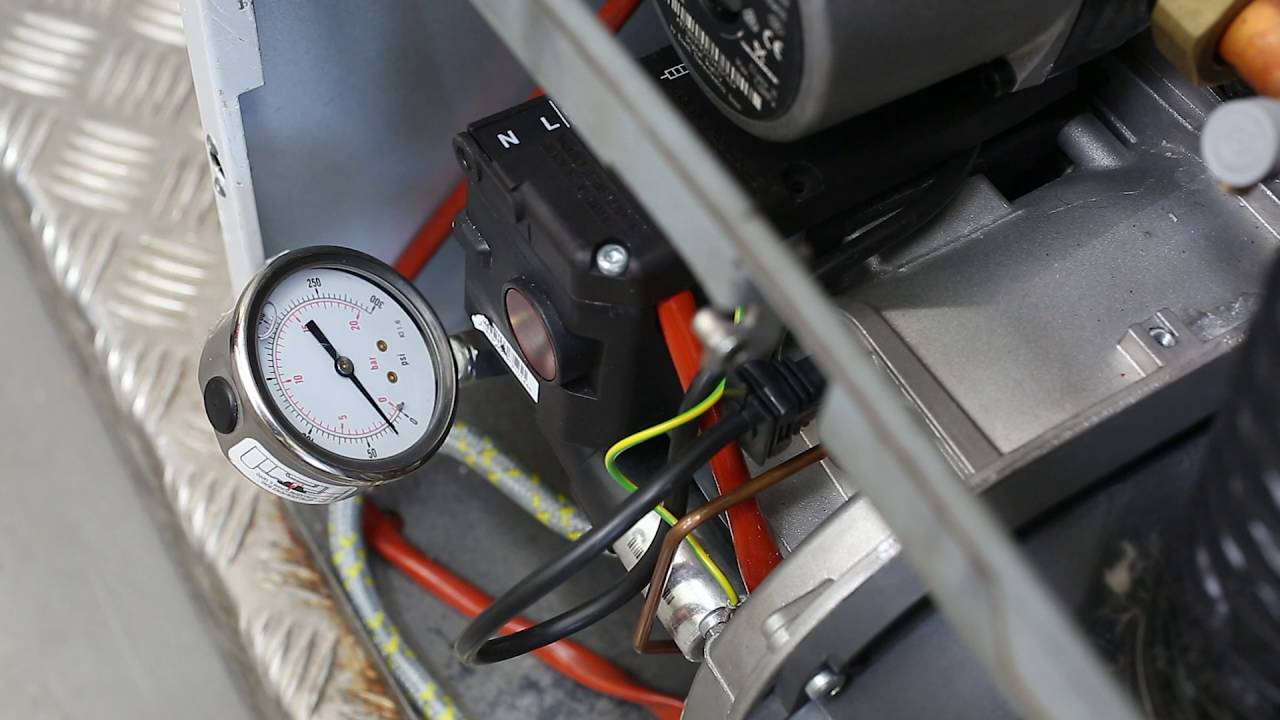

Most boilers have a bleed screw on the oil pump. This is usually located near the burner assembly and is often a small brass fitting. In some systems, particularly newer models, bleeding may also occur automatically during priming. If unsure, consult the boiler manual for guidance.

Step 2: Place a Cloth or Container under the Valve

A small amount of oil may escape during bleeding. Position a container or cloth below the valve to catch any runoff and protect the flooring.

Step 3: Loosen the Bleed Screw

Using the appropriate tool (usually a flat-head screwdriver or spanner), gently turn the bleed screw anti-clockwise. Do not remove it completely. You should hear air hissing as it escapes from the system.

Step 4: Watch for Oil Flow

As the air is purged, oil should eventually begin flowing steadily from the bleed point. When the flow is smooth and bubble-free, the air has been successfully removed.

Step 5: Tighten the Screw Again

Once a clean flow of oil is observed, tighten the bleed screw securely. Be careful not to overtighten, as this may damage threads or fittings.

Step 6: Restart the Boiler

Switch the boiler back on and listen for normal operation. Most systems should reignite immediately once air has been fully purged. If the boiler still locks out, you may need to repeat the process.

Bleeding After Running Out of Heating Oil

Running a boiler completely dry is one of the most common causes of air entering the fuel line. When the system is refilled, trapped pockets of air may prevent the burner from firing. In this situation:

- Bleed the fuel line from the pump

- Reset the system if it locks out

- Repeat once more if necessary

If the boiler still fails to start after two or three attempts, a professional engineer should inspect the system. Continual air ingress may indicate loose fittings or deteriorated oil lines.

Bleeding Radiators vs. Bleeding the Boiler

Many homeowners confuse radiator bleeding with bleeding the boiler. Although both relate to trapped air, they serve different purposes.

Bleeding radiators involves:

- Removing air so hot water fills the radiator

- Using a bleed key to release air at the top

- Restoring heat distribution in the home

Bleeding the boiler involves:

- Removing air from the fuel system

- Ensuring the burner receives clean, uninterrupted oil

- Preventing flame failure and boiler lockouts

In many cases, both tasks may need to be done, particularly after system maintenance or a full drain-down.

When Bleeding Alone Is Not Enough

If trapped air returns frequently or the boiler requires constant bleeding, an underlying problem may be present. Possible causes include:

- Air leaks in the oil supply line

- Perished seals or fittings

- Blocked filters

- Pump pressure issues

- Sludge buildup is restricting flow

- Faulty non-return valves

In such cases, a heating engineer should diagnose the fault. Repeated bleeding without addressing the underlying cause will only mask the real issue and may cause long-term damage.

Preventing Air from Entering an Oil Boiler System

While bleeding is a useful skill, prevention is always better than a cure. To reduce the need for bleeding:

Keep the oil tank topped up

Running dry is a major cause of airlocks.

Service the boiler annually.

Professional servicing removes sludge, checks seals, cleans burner jets and ensures the system remains efficient.

Replace oil filters regularly

Clogged filters can create a vacuum that can pull air into the lines.

Install a quality oil line.

Plastic-coated copper lines resist corrosion and reduce the risk of tiny leaks.

Check joints and fittings

Loose joints are a common source of recurring air ingress.

Ensure system pressure is stable.

Low pressure can disrupt circulation, contributing to air buildup.

With proper maintenance, bleeding should be required only occasionally rather than regularly.

Should You Call a Professional?

Although bleeding is usually safe and manageable for homeowners, certain situations require professional assistance:

- You cannot identify the bleed valve

- The boiler repeatedly locks out after bleeding

- Leaks are visible around the boiler or pipework

- System pressure drops regularly

- The heat exchanger shows signs of corrosion

- The burner stops running after ignition

Calling a qualified oil heating engineer ensures the system is fully inspected and repaired to prevent further issues.

Final Thoughts

Knowing how to bleed an oil boiler can help homeowners maintain efficient and reliable heating performance throughout the colder seasons. By understanding the symptoms of trapped air, following the proper step-by-step process, and carrying out routine maintenance, most heating systems can be quickly restored to optimal working order. However, frequent occurrences may indicate air leaks, fuel contamination or mechanical faults, in which case professional support is recommended.

If you need high-quality heating oil or support with your system, 123 Oil can help keep your boiler operating smoothly all year round. With good care, a well-maintained oil boiler can continue to heat your home efficiently and reliably for many years.

Frequently Asked Questions

Typical signs include cold spots in the radiators, gurgling noises in the system, reduced heat output, repeated burner lockouts, and visible air bubbles in the fuel line.

Yes, bleeding an oil boiler is usually safe for homeowners when done correctly. However, if the boiler repeatedly loses prime or you are unsure of the process, professional assistance is recommended.

Most systems require only a screwdriver or spanner to loosen the bleed screw, a small container or cloth to catch oil and protective gloves. A radiator key may also be needed for bleeding radiators.

Air commonly enters the system after the heating oil runs out, through loose fittings, during maintenance work, or due to sludge buildup and circulation problems.

If the boiler still won’t fire after two or three attempts, there may be a leak, a pump fault, a clogged filter, or a circulation issue. At that point, a heating engineer should inspect the system.